Running supermarkets is about a lot more than just stocking shelves. A supermarket that is running efficiently has dozens of systems, assets, suppliers and operating procedures that need to work together seamlessly or everything comes to a halt. From refrigeration and airconditioning, to POS terminals and utilities, if even one part of the system fails, it can result in lost revenue, wasted products, costly downtime, and unhappy customers.

This is why a holistic facility management system is so important. It’s not just useful – it’s essential.

What is a Facility Management System?

A facility management system is a digital platform that tracks physical assets, services and facility maintenance across a location. In a supermarket, it gives managers real-time visibility over things like:

- Location of various assets across the store

- Status and condition of critical assets

- Routine maintenance

- Service requests

- Supplier management and billing

A great facility management system ensures that managers know exactly what is happening with their facilities and what needs to happen to keep things running smoothly. This includes getting accurate data instantly and digitising processes to avoid relying on error-prone and time-consuming manual processes. With accurate information, decision making can shift from reactive to proactive.

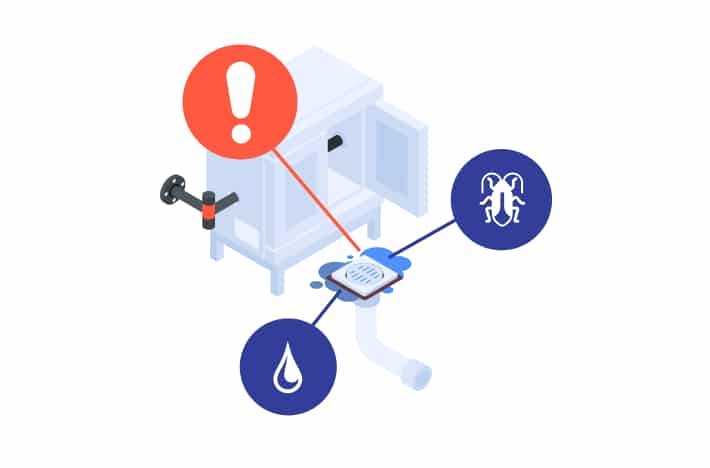

What Are The Risks Of Operating Without A Digital Facility Management System?

Without a structured system for managing facilities and assets, details get missed and things start to fall through the cracks. In a business like a supermarket, even small cracks can start to add up as excess costs and unsatisfied customers.

RISK: Critical System Downtime

Without regular, thought out maintenance in place, supermarkets run a greater risk of critical systems failing. Just some of the systems that could be impacted by poor maintenance include:

- Refrigeration systems, freezers and cold rooms

- Deep fryers and bain maries

- Combi ovens, bakery ovens and provers

- Ice machines, juicers and fish displays

- Packaging machines like sealers and food wrappers

- POS systems and cash registers

- HVAC systems and utilities like lighting and plumbing

- Warehouse assets like forklifts, compactors and floor polishers

When any of these assets aren’t tracked and serviced proactively, they run the risk of breaking down in the worst possible moment. What if the refrigeration system fails overnight and thousands of dollars in stock is lost long before the store opens? These are the kinds of worst case scenarios that a great facility management system helps to avoid.

RISK: Compliance Issues

Depending on the country or state you’re in, electrical, safety and refrigeration assets will often require regular inspections for your supermarket to remain compliant. Without a facility management system to track compliance, problems start to appear. Perhaps scheduled maintenance gets skipped once or twice, or important paperwork goes missing. If your supermarket is found to be non-compliant, it could mean huge penalties and food safety breaches.

RISK: Unseen Costs

If asset servicing and standard operating procedures undertaken by suppliers aren’t captured digitally you run the risk of losing track of costs, having accidental call-outs or missed scheduled tasks.

Why a Facility Management System Is So Important

A great facility management system is a game changer for supermarkets. With real-time visibility, you can react the instant something goes wrong and can proactively manage know immediately what is in stock, what you need to order more of, and what is expiring soon. The system can have automated replenishment alerts when stock levels drop and the recorded data helps you to better forecast demand so you don’t overorder.

You can track assets and keep informed of their servicing dates and repair history to reduce downtime, and with improved workflow tasks that used to take hours can be done in seconds.

Last but not least, a facility management system will help you reduce waste, shrinkage, and lost revenue. Better planning and better monitoring means fresher produce and less stock that need to be thrown away.

To Wrap Up

With so many moving parts, there is no room for guesswork in a supermarket. Thin margins and high turnover require careful planning and structure, making a facility management system a non-negotiable. Protect profit, prevent waste, and ensure that customers always get what they came in for by looking into facility management systems today.